Starsurf® etching

StarSurf® is a surface treatment process enabling to create a rough structure on the surface of implants made of titanium and titanium alloys thus improving their biological performance of osseointegration.

Implants surface finishing plays a crucial role in the success of an implantation surgery. As a matter of fact, the first contact between the implant and the patient’s body is a key step towards its success.

StarSurf® etching process was originally developed for dental application on titanium and titanium alloy Ti6Al4V ELI implants aiming at improving their biocompatibility and therefore patient comfort and safety.

StarSurf® etching process also applies to other fields such as orthopaedics, maxillofacial implants or other customer demands.

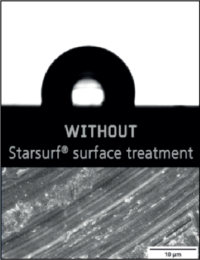

The wettability, a key benefit of StarSurf® surface treatment

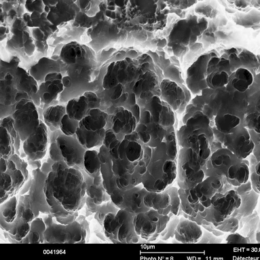

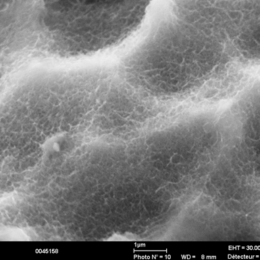

The StarSurf® surface treatment produces 3 roughness levels on the treated implant surface. At the macro and micro scales, the treatment increases the bone / implant contact surface, commonly named BIC (Bone to Implant Contact). At the nano scale, the roughness achieved by the StarSurf® treatment makes the implant surface completely hydrophilic.

SED Starsurf® surface images

Test of wettability on raw and StarSurf® treated surfaces

A technology that optimizes the osseointegration of your implants

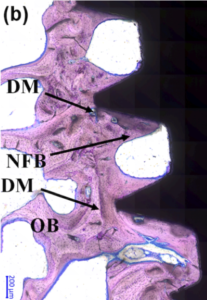

The in vitro and in vivo studies carried out by SELENIUM MEDICAL in collaboration with partner laboratories highlight the impact of StarSurf® treated surface compared to an standard surface. The results of these studies are available for download at the bottom of this page.

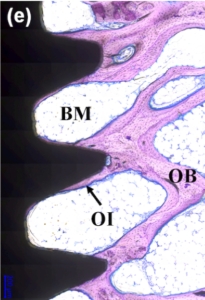

Histological sections at 13 weeks on a standard implant (left) and StarSurf® treated implant (right).

Drill margins after 13 weeks on a standard implant (left) and StarSurf® treated implant (right).

*OB: old bone; OI: osseointegration; BM: bone marrow; NFB: Newly formed bone; DM: drill margins

Clinical studies on patients conducted by customers specialized on dental implants industry, on their own products are currently underway. The first results are very promising and confirm the results of in vitro and in vivo studies carried out by SELENIUM MEDICAL.

Recent and highly efficient equipments

In 2019, SELENIUM MEDICAL installed a new and modern workshop with fully automated equipments, including sandblasting units, a gel masking cell for implants requiring partial treatment and one chemical etching unit to perform StarSurf® treatment. This new equipment aims at ensuring reproducibility of the process and also at meeting customer requirements in terms of production capacity (several hundreds of thousands implants per year), product traceability and compliance with applicable regulations.

Need a packaging solution for your implant?

SELENIUM MEDICAL keeps innovating and offers new packaging solutions for the dental implant industry. Discover the SoKlean, a smart “no touch” holder that protects and enhances your implants.